ENERGY CONSERVATION IN FACTORIES

SHIFT EFFICIENCY

Saving millions of baht

0 Baht

0 kW

0 Tons

0 Baht

WHAT IS ENERGY EFFICIENCY?

In an era of rising energy costs, energy-saving strategies in businesses and factories are essential. Effective energy conservation can significantly reduce operational costs. The key to saving energy in factories lies in implementing guidelines and measures to minimize energy use, focusing on enhancing the efficiency of various equipment in a thorough, careful, and cost-effective manner through an efficient energy management system.

Energy Efficiency is an end-to-end approach to reduce your energy consumption. After carrying out a thorough energy audit to monitor all your major equipment such as chiller, cooling tower, pumps, air compressors, boilers, lighting, and AHUs, we will be able to define a custom-made program to reduce your energy consumption.

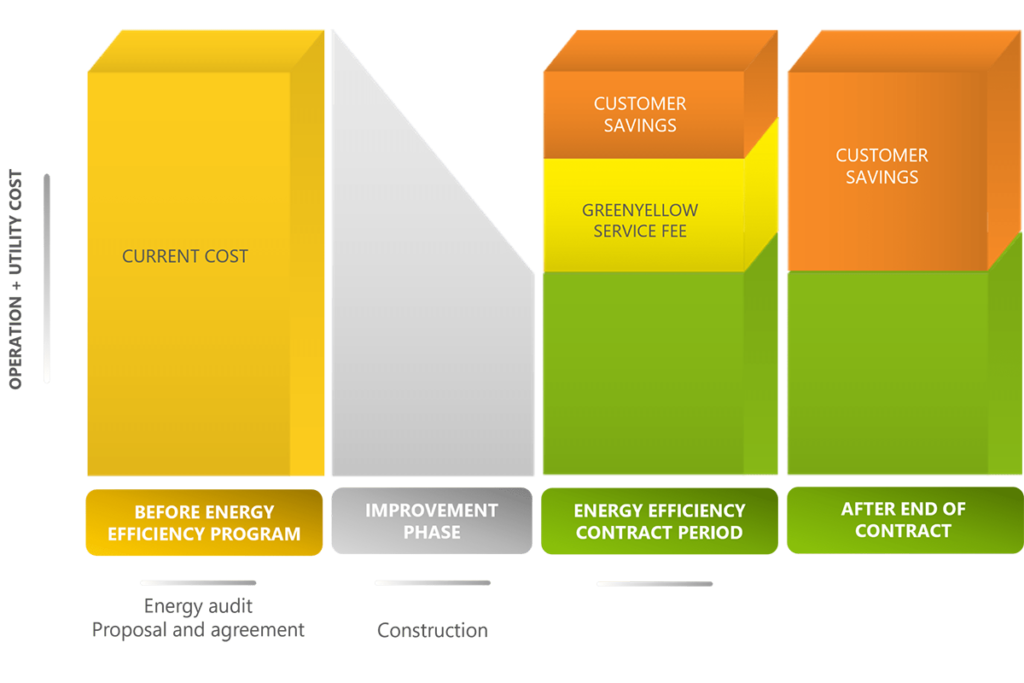

Building up on our B.O.O.T. approach, we will finance the entire retrofitting or replacement of underperforming equipment, ensure operation and maintenance, and guarantee their performance. GreenYellow's service fee is based on a percentage of the savings, via an Energy Efficiency Agreement (Service Agreement).

ENERGY EFFICIENCY SOLUTIONS

ENHANCE INDUSTRIAL EFFICIENCY WITH AN EFFICIENT CHILLER SYSTEM

As industrial factories expand rapidly due to economic growth, the installation of chillers, which are large refrigeration machines, are crucial for reducing the temperature of machines and air conditioning has become common. However, without proper planning, these installations can lead to higher energy costs and maintenance expenses.

GreenYellow specializes in designing, supplying, and installing chiller systems tailored to your needs. We also optimize existing industrial chiller systems by improving the Air Handling Units (AHUs), installing Variable Speed Drives (VSDs), and using a Chiller Plant Management System (CPMS) for cooling. These improvements enhance machinery efficiency, reduce electrical energy use, and ensure more orderly system management.

COMPRESSED AIR SYSTEMS: INCREASE PRODUCTION EFFICIENCY AND REDUCE COSTS

Many organizations aim to increase productivity while simultaneously reducing production costs. The compressed air system is a vital component in factories, supplying air to various equipment and tools essential for industrial operations. Continuous use can cause the system to deteriorate, reducing efficiency and inadvertently increasing costs.

GreenYellow offers expertise in improving air compressor systems. Our team of experts inspects, analyzes, and optimizes air compressors to ensure they operate efficiently, reducing energy loss and increasing consistent air pressure. This helps machinery and equipment run smoothly, enhances durability, and reduces downtime, ultimately lowering company costs.

ADDITIONAL EQUIPMENT

Pumps / Cooling Towers

Boilers

Lighting system

ENERGY AND CHILLER PLANT MANAGEMENT SYSTEMS

Energy Management System (EMS)

Chiller Plant Management System (CPMS)

ENERGY EFFICIENCY SOLUTION PROCESS

01

Understand and analyze your energy consumption. By gaining deep insights into energy consumption.

02

Define an energy efficiency program tailor-made to your needs.

03

Optimization and renovation of your equipment. GreenYellow invest 100%.

04

Track your new energy consumption and equipment performance analysis, monitoring, and consumption report.

05

Guaranteed performance. Share of Energy Savings.

LIMITLESS BENEFITS

SAVE ON INVESTMENT COSTS

Because GreenYellow invests in the optimization of energy systems.

REDUCE ELECTRICITY COSTS

ENERGY SAVINGS

PERFORMANCE GUARANTEE

NO OPERATION AND MAINTENANCE FEE (NO OPEX)

FULL-SCALE SERVICES CUSTOMIZED

To specific business needs.

FOCUS YOUR TIME AND RESOURCES

On your core business.

A MODERN ENERGY SYSTEM

To significantly reduce carbon dioxide emissions.

SAVE SUBSTANTIALLY ON ELECTRICITY COSTS

SEE OUR ENERGY EFFICIENCY PROJECTS

Schneider Electric

Optimization: Chillers, cooling tower, and pumps replacement, Automated CPMS

Energy savings: 3.5 GWh/year

Hilton

Optimization: Chillers, cooling tower, and pumps replacement, Automated CPMS and water treatment

Energy savings: 1.35 GWh/year

Holiday Inn

Optimization: Chillers, cooling tower, and pumps replacement, Automated CPMS and water treatment

Energy savings: 1.4 GWh/year